Overview of ControlEdge RTU 2020

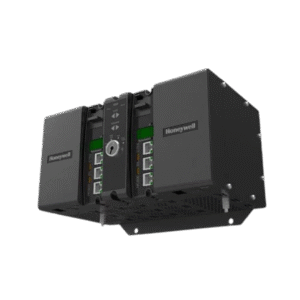

The ControlEdge RTU 2020 from Honeywell is a powerful remote terminal unit engineered for efficient monitoring and management of distributed industrial assets. Built to perform in challenging environments, this RTU enhances productivity and reduces field maintenance through reliable remote access, diagnostics, and asset intelligence. Its design supports seamless deployment in remote locations and is optimized for solar-powered operation, making it ideal for industries such as oil and gas.

Key Capabilities

The ControlEdge RTU 2020 brings together a suite of advanced features tailored for robust automation:

- Rugged Operation: Handles extreme field conditions while consuming minimal power—perfect for solar-powered remote installations.

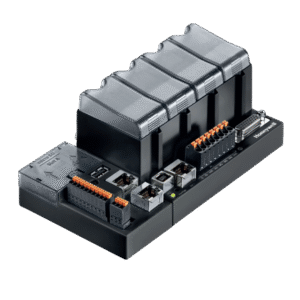

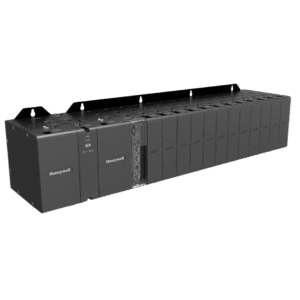

- Redundant Controller Setup: Boosts system availability with built-in controller redundancy, eliminating the need for external I/O communication switches.

- Smart I/O Architecture: Supports HART-enabled onboard and expansion modules, making integration and scalability straightforward.

- Simplified Installation: Removable terminal blocks reduce wiring complexity and save time during cabinet integration.

- Integrated Wireless I/O: No extra modules required to connect ISA100 wireless instruments—both wired and wireless devices use the same configuration environment.

- Field Device Integration: Features built-in HART I/O and seamless ISA100 connectivity via Field Device Manager.

- Scalable Management: Supports centralized management of thousands of RTUs, drastically cutting down data collection and diagnostic time.

- Flow Metering: Complies with API 21.1 and 21.2 standards for both gas and liquid measurement.

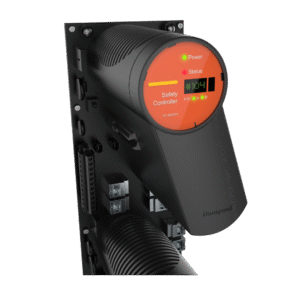

System Operation

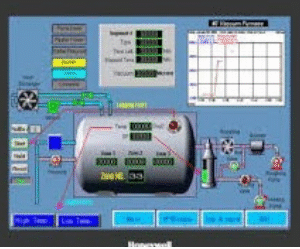

Programming and maintenance are handled through ControlEdge Builder, an intuitive development platform compliant with IEC 61131-3 standards. This tool offers multiple programming languages including Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), and Sequential Function Chart (SFC), enabling flexibility and ease of use.

The RTU’s communication capabilities are a standout feature, allowing integration across diverse networks. Unlike conventional PLCs, the ControlEdge RTU 2020 supports advanced data logging and backfilling. This ensures that critical data is retained locally during communication dropouts and can be synchronized once connectivity is restored.

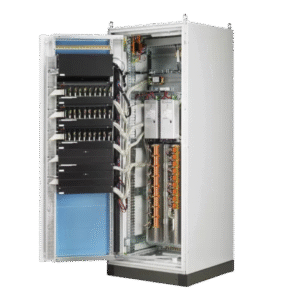

Industry Challenges Addressed

Designed to meet the demands of complex field automation, the ControlEdge RTU 2020 offers a cost-effective and high-performance solution for:

- Wellhead Control and Monitoring

- Flow Data Collection and Metering

- Compressor and Pump Control

- Block Valve Operations

- Remote Gas Station Automation

- Multi-well Management with Expandable I/O Requirements

By significantly minimizing the need for site visits and reducing diagnostic time from hours to minutes, this RTU enhances operational efficiency and delivers actionable insights from field data.