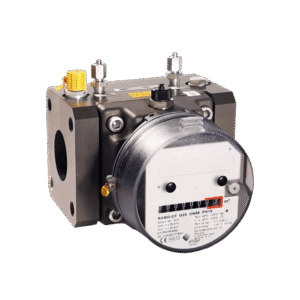

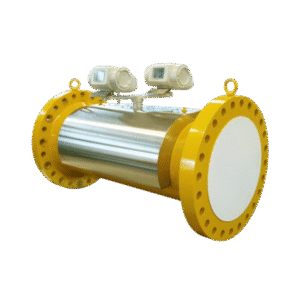

Overview of the Turbine Gas Meter SM-RI-X

The Turbine Gas Meter SM-RI-X from Honeywell Elster is built to withstand the harshest environments—whether offshore or onshore. Designed for durability and precision, this meter delivers consistently high accuracy from its first calibration through to the end of its long service life. Its exceptional long-term performance has made it a benchmark in large-scale gas metering and a preferred choice in many accredited calibration laboratories around the globe.

Trusted in High-Demand Applications

Used extensively across the full gas value chain, the Turbine Gas Meter SM-RI-X is ideal for custody transfer processes—from production sites to pipeline transmission stations, and onward to city gate and local distribution points. It also serves a critical role in large-scale industrial and commercial settings, including power generation plants, where precise gas measurement is essential.

Alternative for Smaller Sizes

For installations requiring sizes smaller than DN200 (8 inches), Honeywell provides the TRZ2 turbine gas meter, which is available in diameters from DN50 to DN150 (2 to 6 inches), offering the same trusted technology in a compact form.

Operating Principle and Design Innovation

The operation of the SM-RI-X is based on the principle of fluid-driven motion: the incoming gas causes a turbine wheel to rotate, with its speed directly proportional to the gas volume passing through. A proprietary X4X flow conditioner is positioned upstream to neutralize disruptions such as swirls or irregular flows caused by nearby fittings. This ensures stable conditions for precise measurement.

Post-conditioning, the meter’s cross-sectional area is narrowed to increase gas velocity, enhancing the turbine wheel’s response. This setup allows the Turbine Gas Meter SM-RI-X to deliver reliable readings even at lower flow rates and pressures.

Durability and Efficiency in Every Detail

The turbine wheel is mounted on a robust shaft supported by long-life ball bearings, minimizing wear and reducing maintenance needs. Rotations are transferred via a magnetic coupling system to an 8-digit mechanical counter housed in a non-pressurized index head. Additionally, the outlet has been engineered to reduce pressure drop and promote ideal downstream flow conditions.